February 2026

Join us at NAB 2026, April 19-22, in Las Vegas.

Click on the picture above to register for FREE (a $159.00 value) to attend NAB 2026.

March 2025

Get your FREE exhibit pass for NAB 2025

Click on the image above to register for a FREE NAB 2025 exhibit pass and join us in the North Hall at booth N1259 in the Las Vegas Convention Center April 6-9, 2025 to see the lastes innovations in RGB-backlit LCD keys.

August 2024

ibc 2024 show video

This video gives you a preview of the innovations we will showcase at the ibc 2024 trade show in Amsterdam.

August 2024

Check out our LCD Keys in the official ibc 2024 promo video

Our trade show demo from last year is briefly featured in the official promo video for ibc 2024.

July 1, 2024

We Are Moving ...

After more than 20 years at the ZENTEC Center for Technology,

Entrepreneurship and Cooperation, we are moving down the road to the Unternehmerzentrum

(Center for Entrepreneurship) Miltenberg.

Effective July 1, 2024 our new corporate address is:

[E³] Engstler Elektronik Entwicklung GmbH

Auweg 27

D-63920 Grossheubach

Germany

Our new phone number, also effective July 1, 2024, will be

+49 (0)9371 9164500.

Please update your files accordingly. Of course, we can still be reached through our website at

www.e3-keys.com.

April 14, 2024

Introducing TE6432 at NAB 2024

TE6432: same features as the SE6432 in a smaller 19.6mm x 17.6mm footprint

April 10, 2024

[E³] to reveal NEW TE6432 switch series at NAB 2024

The TE6432 series of programmble, RGB-backlit LCD switches with Multi-Segment Color MSC™ will be revealed at NAB 2024 in Las Vegas this week.

April 2024

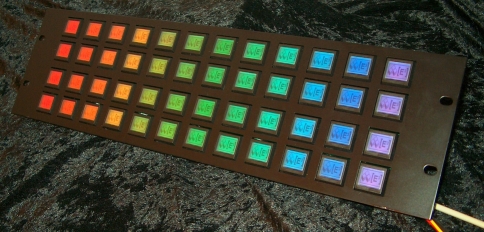

SE6432 with Multi-Segment Color MSC™

SE6432 switches with Multi-Segment Color MSC™ in CP1201, CP1701 and CP1203 rackmount control panels.

August 29, 2023

[E³] back at ibc as part of the German pavilion in Hall 3.B45b

We back at ibc in Amsterdam, September 14-18, 2023, exhibiting the latest innovations in RGB-backlit LCD keys as part of the German pavilion in Hall 3.B45b.

We will be showing the all-new SC6432 switches with updated electronics replacing the SA/SB series and introducing the SD6432 and SE6432 switches with Multi-Segment Color, another industry first

for RGB-backlit LCD keys.

July 13, 2023

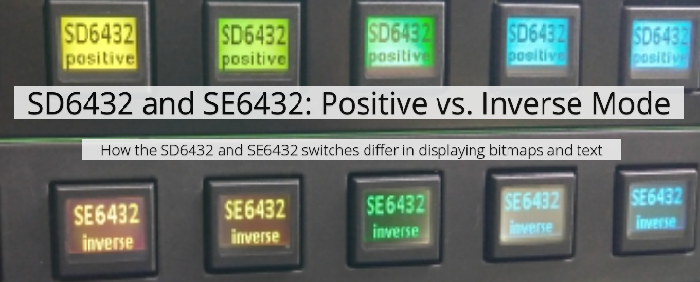

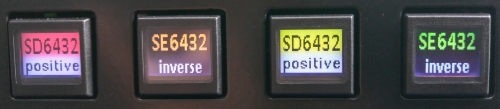

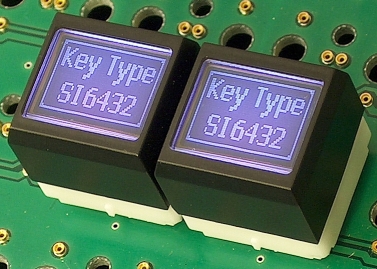

SD6432 and SE6432: Positive vs. Inverse Mode

The SD6432 and SE6432 are basically the same switch. The SD6432 displays black text on color background in Positive Mode and the SE6432 displays color text on black background.

Based on your preferences you may chose either version.

What is Positive and Inverse Mode?

The image below shows the effect of the Positive Mode of an SD6432 switch (left) compared to the inverse SE6432 display (right). In the SD6432 Positive Mode the pixels of

the LCD will be transmissive and allow the RGB-background color to show. Turning the pixels on will create black-on-color text. In the SE6432 the pixels are black by default

and turning the pixels on will create color-on-black text.

In combination with the new inverse DFSTN LCD, this provides a better contrast and viewing angle for superior readability and user guidance. The RGB colors created by the

quad-LED backlighting remain uniform across large control panels thanks to the improved automatic calibration system used during the manufacturing process. With this

proprietary system we measure and adjust the individual LED crystal color output to create uniform colors throughout the RGB spectrum.

In addition, both SD6432 and SE6432 switches feature Multi-Segment Color MSC™ in the upper and lower display segment.

June 8, 2023

SD6432 & SE6432 with Multi-Segment Color MSC™

The all-new SD6432 and SE6432 switches introduce Multi-Segment Color MSC™, the ability to use two different RGB-colors in the upper and lower segments of the display. This allows users to group switches together by color and still use a different color to indicate operating status such as ON/OFF or volume settings on a microphone, for example.

In combination with the new inverse DFSTN LCD, this provides a better contrast and viewing angle for superior readability and user guidance. The RGB colors created by the quad-LED backlighting remain uniform across large control panels thanks to the improved automatic calibration system used during the manufacturing process. With this proprietary system we measure and adjust the individual LED crystal color output to create uniform colors throughout the RGB spectrum.

April 14, 2023

NAB 2023 Show Exhibit Preview

Watch this video to see a preview of our NAB 2023 show exhibit with SC6432, SD6432 and SE6432 Series LCD keys.

April 16-19, 2023

[E³] highlights new product features at NAB 2023

[E³] will, once again, showcase the latest innovations in

RGB-backlit LCD switches at NAB 2023 in Las Vegas from April 16-19. This year, we will focus on new product features in the all-new

SC6432, SD6432 and SE6432 switches.

[E³] will, once again, showcase the latest innovations in

RGB-backlit LCD switches at NAB 2023 in Las Vegas from April 16-19. This year, we will focus on new product features in the all-new

SC6432, SD6432 and SE6432 switches.

The SD6432 and SE6432 switches are identical, but operate in either positive or inverse mode in order to take full advantage of the superior viewing angle and contrast of the new DFNTS displays. These switches also offer MSC™ Multi-Segment Color, the ability to utilize two different RGB background colors in the upper and lower segment of the LCD. This innovation allows for better user guidance and information clarity by grouping switches while adding system status indications.

All new switches are fully backwards compatible with identical dimensions, pinouts. command sets and interface for an easy transition path for existing customers and to provide ongoing support for our large installed base in master control, routing and intercom systems.

March 2023

Get a FREE exhibit pass to [E³]'s booth C6938 at NAB 2023

Click on the image below to register for a FREE exhibit pass and schedule your personal demonstration of the new SC, SD and SE switches at our booth C6938 in the Bavarian Pavillion in Center Hall.

March 2023

Start of Series Production of SC-SD-SE-SR Switches

Introduced as portotypes at last year's NAB show, the all-new SC6432, SD6432 and SE6432 switches have undergone final revisions and started series production as schedued during the first quarter of 2023. In addition,the special order version SR6432, after undergoing final reviews for the demanding environments of military applications, will become available at the start of the second quarter as well. These new versions will be complimented in the second quarter by the new SC3624 switch with Legacy Mode™ protocol to continue our ongoing support for customers and their existing hardware systems.

All new switches are backwards compatible to the previous generation SA and SB switches providing a transition path for our existing customers. The new switches are identical in form, fit and function with the same dimensions,pinout, commands and interface while adding improvements and new prouct features such as MSC™ Multi-Segment Color.

September 2022

ibc returns to RAI Amsterdam

The ibc show is back LIVE at the RAI in Amtserdam.

Although we are unable to participate this year, [E³] wants you to be able to explore our

RGB-backlit LCD switches, control panel solutions and product introductions.

We have, therefore, created an online exhibit space to showcase our latest product introductions,

innovations and panel solutions.

Click on the links below for

March 2022

[E³] offers FREE exhibit pass to NAB 2022

Click on the link above and register to attend the NAB 2022 show in Las Vegas on us.

July 2021

[E³] to launch 3 NEW switch versions at NAB 2022

While the COVID-19 pandemic has impacted all our personal and professional lives and required us to change and adapt to new realities,

we welcome the return to a sense of normalcy. One such step is the anticipation to meet our customers and colleagues from around the

world at the upcoming NAB trade show in Las Vegas.

[E³] will mark this occassion with the public introduction of three new switch versions, the SC6432, SD6432 and SE6432. All NEW

switches feature significant product improvements and additional features including the unique Multi Segment Color MSC™ backlighting option.

Stay tuned for more information on product innovations and design details as we move closer to the trade shows.

March 2020

Cleaning and Disinfecting Sxnnnn Switches

Due to the outbreak of the Coronavirus Disease 2019 (COVID-19) we have received a number of requests for information on how to best clean and disinfect the Sxnnnn switches.

The keycap of the Sxnnnn keyswitches is made from Plexiglas® HW55 (acrylic glass). This material is a copolymer of methyl methacrylate (MMA) with comonomer constituents.

While the switch surface is resistant to weak acids, weak caustic solutions, fats, oils and turpentine, they are NOT resistant to concentrated acids, oxidizing acids, concentrated caustic solutions, and alcohols. The switch surface can best be cleaned and disinfected with a microfibre cloth dampened with hot water and regular household detergent. Care should be taken not to cause running water to run down the sides of the switches, which may cause shortcircuits on the PCB.

We understand the concerns of our customers and would like to refer you to the

Interim Guidance by the CDC for Businesses and Employers, which you can find here

[Links to CDC no longer active. Updated 11/11/24].

For more details on cleaning and disinfecting the Sxnnnn switches please click here.

August 2019

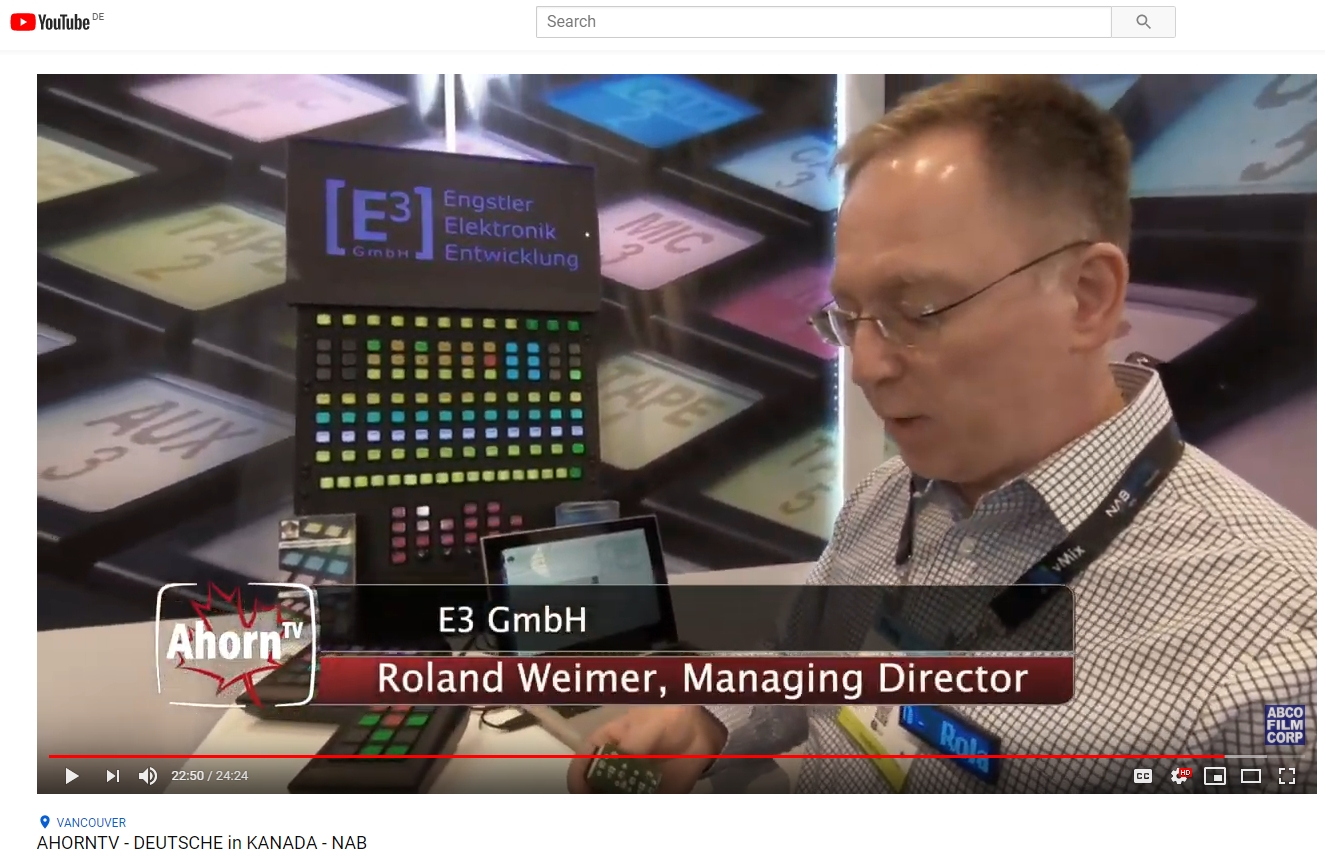

[E³] at NAB featured on Ahorn TV

Watch the recent segment on [E³] products at NAB on Ahorn TV, a German language program in Canada.

April 8-11, 2019

NAB Show 2019

Come visit our booth in Hall C 8033 at NAB 2019 in Las Vegas.

February 2019

[E³] launches revamped website

After expanding its social media presence and in time for NAB 2019, [E³] is launching its revamped website. With streamlined product information and access to context linked product information we hope to offer a better user experience and provide more and more useful information to our visitors and customers. In particular, we are linking product information to our social media presence and vice versa. We will also continuously update the information aligned with all our marketing channel efforts.

As a result of the expanded legal requirements for compliance with EU and US laws, we have created a single source for all our compliance certifications.

Our next step will be the extension of our support department knowledge base to a FAQ section that will be added to our website. We expect this effort to offer our customers quick and efficient access to relevant support information.

January 2019

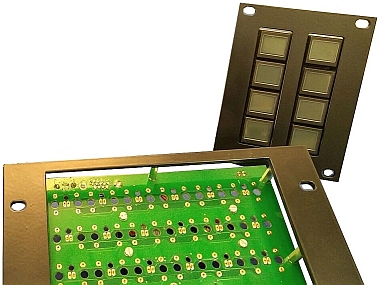

C3 Panels for Military Applications

[E³] continues to deliver highly specialized command, control and communications panels for military applications. After delivering desktop panels for integration in naval command centers for the Chilean Navy last year, [E³]'s military sales continued in 2019 with a renewed contract for SM6432 switches by the US Air Force and the delivery of custom control panels for a NATO partner.

Roland P. Weimer, managing director of [E³] and president of our US distribution partner, I/O Universal Technologies Inc., explained: "For more than 25 years, we have designed and manufactured control panels for military applications such as naval mission controls, airborne warning systems, UAV guidance & control, flight simulators, surveillance systems and mission critical consoles. This includes COTS systems as well as custom designs. Our control panels support today's war fighters with innovative solutions on an ever more complex battlefield."

April 2018

Ready ... Set ...SHOW!

The new NAB 2018 setup went so smoothly that we had time to post these two short videos.

Our new trade show display includes the desktop panels CP0304 and CP0604 as well as five rack-mount panels CP1201, CP1203, CP1204 , CP1701 and a custom control panels CP0604-4E. Six of the CP panels are controlled from a single PC. The units demonstrate dynamic menu structures using bitmaps, text and dynamic text, RGB color paletes and distributed control of panels from another panel via CP Control software.

October 2015

Oslo Opera House customizes stage controls with custom CP panels

When the Oslo Opera House decided to upgrade their stage control system they turned to [E³] for a custom control panel. The unit interface with the existing hardware via RS232/USB from a single controller.

The stage management desk layout, however, made it necessary to have two separate keypads.

Instead of using two separate panels, [E³] designed a custom panel with 2 keypads, one of which is connected to the main units via a ribbon cable extension. This approach not only simplified the software integration, but reduced the hardware development cost as well.

[E³]'s capability to design, manufacture and deliver small batch production runs sealed the deal.

December 2016

Social Media Presence

Partnering with our US distribution partner, I/O Universal Technologies, Inc., we have expanded our social media presence to include Facebook, LinkedIn and YouTube to provide more channels for product information and tutorials on the LCD key technology.

Instructional videos and hands-on tutorials will allow us to demonstrate the various product features, provide product support and assist customers in the integration of our intelligent LCD switches in their products.

January 2016

[E³] launches YouTube channel

In cooperation with our US-based distribution partner, I/O Universal Technologies, Inc., we have started our own YouTube channel to bring you more information and tutorials about our LCD key technology. We will be posting examples of what you can do with our switches and control panels and how it is done.

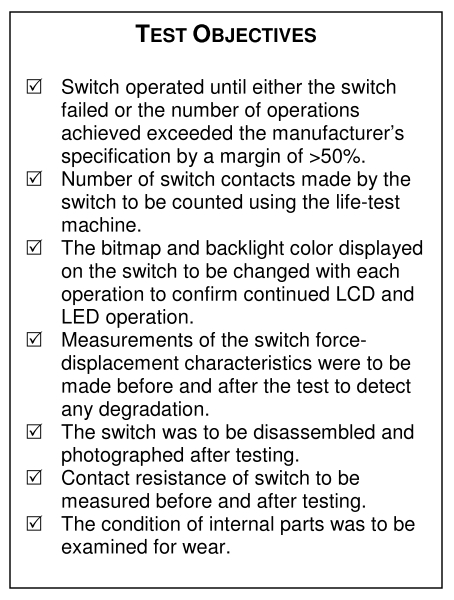

February 2006

Not just intelligent, but TOUGH!

RGB-backlit LCD keys from [E³] surpass lifetime test specifications

Combining a graphical LCD display with RGB-backlighting in a push-button switch has made the SA keys from [E³] the industry leader in intelligent switch design. Their capability to display changing functions in text, graphics or animation on a 64 by 32 pixel matrix with backlighting in over 10,000 calibrated colors had set the new standard for smart switches. But how would they hold up to constant use?

Devlin Electronics, the UK keyboard specialist and our distribution partner, put this question to the test.

The SA switches are used in many commercial and industrial applications, including many 24/7 installations in broadcast centers worldwide. That makes reliable operation over many years as important a requirement as the ease of integration and use.

The new [E³] SA LCD switch was designed to exceed 3 million operations in its working life, three times the life of earlier generation switch technology. To ensure reliability the mechanical design of the switch is completely new, with a tactile dome assembly and four support springs in a structure that provides effective over-travel protection. The purpose of this development was to produce a more flexible and versatile device combining a longer working life with better electronic performance and a more user-responsive switching action. Hard evidence that the switch is capable of meeting its design specification was inevitably going to be of great interest, so Devlin decided to use in-house test facilities to confirm that the published life expectancy is a reliable figure. A life test would also detect mechanical deterioration such as aging of the dome assembly, which frequently leads to early loss of the tactile feel of an otherwise functional switch.

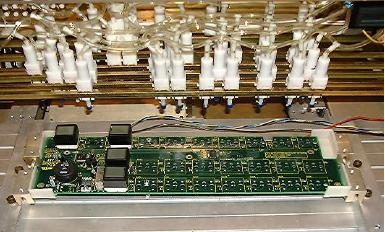

Accelerated Testing

The switching function, the backlight function and the LCD display screen were all to be monitored during the test. An accelerated life test was devised, using Devlin's in-house automated life testing equipment to operate a switch sample installed in a commercially available product.

The Testing Program

A test program was devised to run the life test apparatus, monitor the switch contact and change the display of the switch. A PC was used to control the test machine through an RS232 port and also to monitor the switching function and control the status of the [E³] keyswitch LCD display. The program monitored the keyswitch contact every time the switch was depressed. It would expect a response from the circuit within 300ms, if this was not received then an error would be logged and the test would continue. The program was therefore able to detect any missed operations.

Test Conditions

A sample SA6432 switch was tested in a KSA-026-A2A keyboard developed at Devlin, using design guidelines recommended by [E³]. This setup should therefore be representative of the conditions under which the switch would be used by Devlin customers. The assembled keyboard was mounted on the base-plate of a proprietary keyswitch life test machine which employs air powered actuators to depress the switch. The switching force used was set to be approximately twice the manufacturer's specified switch operation force. Testing, at a rate of 3.4 cycles / second, continued until the total number of operations was approaching 5 million. At this point the operation was terminated and the switch was carefully disassembled to reveal the internal components for examination and photography. The parts that were of most interest were the switch contacts, the carbon impregnated pill, and the silicon dome.

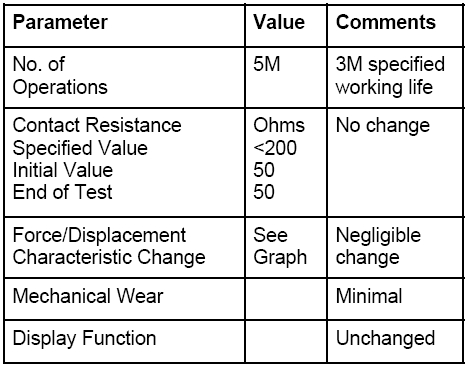

Summary of Results

At the end of the test process the switch was still operating, the LED Backlight and the LCD display appeared unaffected. On visual inspection it was clear that there was a minimal amount of debris in the switch and all components were intact. The carbon impregnated pill showed some signs of deformation where it made contact with the switch contacts. Contact resistance was measured as 50 Ohms before and again after the test. This value, effectively unchanged by the number of operations, was well within the original specification.

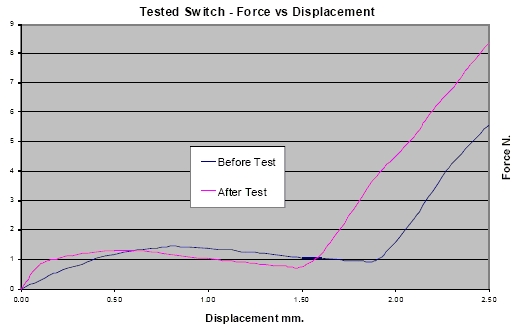

Measurements of the switch force-displacement characteristics were performed before and after the test. The shapes of the resulting curves were the same, showing the feel of the switch did not deteriorate after almost 5 million operations. A shift in distance of 0.4mm at which resistance is encountered was measured, but considered negligible as it would not be noticed by the user.

Conclusions

The test conclusively proved the durability of the switches. After the test the switch was still in good condition and was continuing to function well. The most important results noted were the contact resistance and the force-displacement curve of the switch after the test. These two parameters remained almost unchanged from their before-test values.

Measurements of the switch force displacement characteristics were performed before and after the test. The shapes of the resulting curves were the same, showing the feel of the switch did not deteriorate after almost 5 million operations. A shift in distance of 0.4mm at which resistance is encountered was measured, but considered negligible, as the user would not notice it.

The SA switches have proven that they are not just intelligent, but tough. The reason for this superior performance lies in their mechanical design. The keycap and switch housing are designed to transfer the force applied by the key press from the top of the switch though the keycap wall to the switch base. When the key is depressed with full force, the bottom of the switch housing will rest flat on the circuit board and, thereby, transfer all excess force to the PCB before the contact element is damaged. This means that even after millions of operations the contact element is not damaged and the mechanical operation is not affected. This design has the additional advantage that the LCD glass remains isolated from the operating force of pressing the key.

January 2004

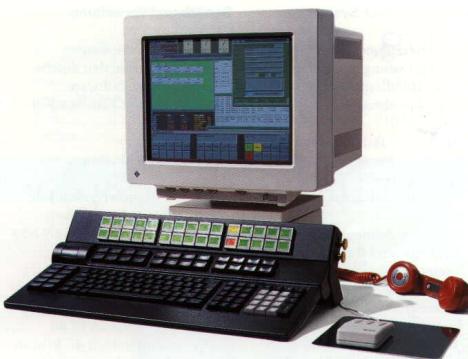

History of the LCD Key Technology

It all started in 1978 with an IBM Technical Disclosure Bulletin (Vol. 21 No. 2 July 1978) where S. Bigbie et. al. published their idea about a programmable key/display/switch device. The same year Alan Bagley of Hewlett-Packard patented a calculator with electronically alterable key symbols (US patent 4,078,257) Nice as these ideas were, it proved to be more difficult to come up with a workable switch design that integrated an LCD in a key top and make it work. Many tried and failed.

The First Programmable LCD Pushbutton Switch and Programmable LCD Keyboard

It took six years until 1984 when Reinhard Engstler, a computer science student in Germany, turned the idea of one of his professors for a programmable LCD keyboard into a fully functioning push-button design with integrated graphic LCD display and incorporated them in a programmable keyboard. The keyboard displayed different special characters for scientific notations.

The first programmable LCD pushbutton switch and the first programmable LCD keyboard were born.

Reinhard Engstler quickly became the Director of Development at LcBloc Computer Technologie GmbH & Co. KG. and oversaw a development department with 10 hardware and software engineers to set up production for programmable LCD pushbuttons and keyboards.

For this development, Reinhard Engstler, together with Dr. Müller, received the Innovation Prize of the Franzis-Verlag for LC Key/Keyboard.

The Second Generation

By 1987, Hohe Electronics GmbH & Co. KG had acquired the LCD key technology and Mr. Engstler, as director of R&D, developed the second generation of LCD switches and proprietary control electronics including the integrated ASIC in each LCD switch.

The LC Board EM2.34 programmable keyboard with 34 LCD function keys received the Gold Medal for Best Product at the Leipzig Industrial Fair.

In 1994, Mr. Engstler, together with Mr. Weimer and three partners, participated in a Management Buy-Out to form HE Electronics, Technologie & Systemtechnik GmbH. Mr. Engstler continued in his position as director of R&D while Mr. Weimer oversaw the marketing and sales activities of the LCD key business.

The LCD keyboard development culminated in the design of the TANK (Technically Advanced Network Keyboard) for TTSI. This keyboard combined a PC, Sun and serial interface with expansion modules and could simultaneously control PC, SUN and real-time applications as well as over 700 phone lines for financial services applications on Wall Street.

Mr. Engstler also developed the second generation ASIC for the new Trend series of LCD pushbutton switches as well as numerous customer specific I/O systems.

One of these designs was the T2 keyboard for TTSI with patented software to control any command in any application, bi-directionally and via the internet. This technology was also integrated into the Sybil phone by ISI.

In 1999, Rapid Technology Interfaces Ltd. acquired the LCD key technology from HE Electronics. Mr. Engstler was named General Manager of the RTI Keyswitch Division and Mr. Weimer Director of Sales and Marketing.

The Third Evolution™

In 2001, Messrs. Engstler and Weimer decided to form a new company dedicated to the development of advanced LCD key technology products.

After a year of development

[E³] Engstler Elektronik Entwicklung GmbH began operations in the ZENTEC Technology & Innovation Center specializing in the development of programmable LCD keyswitches and custom I/O systems.

Here are a few highlights of the accomplishments of [E³] since 2003:

- [E³] acquires global master license from G&R Associates for use of patented T2 software technology for use in multi-application environments.

- Advanced Technology version of LC Trend series switches including extended temperature range, tri-color (red, green, blue) backlighting, additional brightness settings, etc.

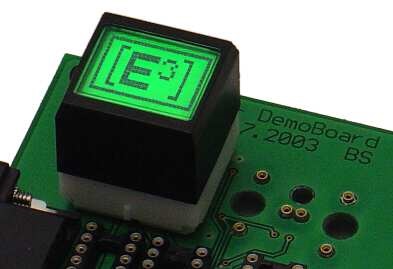

- [E³] introduces DS0000 DemoBoard development and prototyping system.

- SP0000 socket pins allow for "hot-pluggable" field exchange of SA series switches with no difference in built-in height.

- [E³] develops new control electronics for third generation LCD keyswitches including high-resolution versions and mechanical construction/tooling for new switch designs

- [E³] introduces the SA series of RGB-backlit LCD push-buttons at ibc trade show in Amsterdam in September of 2003. SA switches feature 64 RGB colors calibrated for uniform background color.

- Volume production of SA series switches with resolutions of 32x16, 36x24 and 64x32 pixels with 64 RGB background colors begins.

- [E³] signs distribution agreements for the United Kingdom, the United States and Canada, Japan, Turkey and Belgium with shipments going to more than 20 countries worldwide. [E³] exhibits regularly at the NAB show in Las Vegas and ibc in Amsterdam.

- SA switches surpass durability testing to achieve more than 5 million switch cycles proving that the LCD keys from [E³] are not just intelligent, but tough.

- Upgraded control electronics for the SB switches allow for more than 10,000 RGB colors and more flexibility with interface protocols and enhanced key commands.

- [E³] introduces the SI series of inverse LCD switches for avionics applications with improved sunlight readability and SM series for military applications with extended command set and environmental parameters.

- Building on more than 40 years of experience with control panel, keyboard and LCD switch design and development [E³] expands its product offerings with custom control panels designed to customer specifications. Military and industrial users require design flexibility and robustness for demanding

applications with unique technology solutions for power management, temperature compensation and system interfaces.

The Future

What will the future of the LCD Key Technology bring?

[E³] is committed to the continuous development of state-of-the art display switch solutions. At any given time we are working on numerous product improvements as well as technological innovations that allow our customers to incorporate the latest advances in technology to market.

Join us at NAB 2026 for FREE

See how you can register for FREE using code NS7368

NAB 2025 Setup

1...2...3...Show

NAB Show Video

See the preview of the NAB show video on YouTube

Get your FREE exhibit pass for NAB 2025

Join us at NAB in Las Vegas April 6-9, 2025

ibc 2024 show video

Get a preview of our ibc 2024 innovations

ibc 2024 promo video

Our LCD keys are featured in the official ibc 2024 promo video

We Are Moving ...

New corporate address and phone number starting July 1, 2024

Introducing TE6432 at NAB 2024

TE6432: same features as SE6432 with smaller footprint

TE6432 to be revealed at NAB 2024

[E³] will reveal the latest product innovation at the upcoming NAB show in Las Vegas, April 14-17.

Register for FREE

Join us at NAB 2024 in Las Vegas

SE6432 Standard Mode with Multi-Segment Color MSC™

Watch a short video with SE6432 switches in CP panels

[E³] at ibc in the German pavilion Hall 3.B45b

[E³] is back at ibc in Amsterdam as part of the German pavilion.

SD6432 and SE6432: Positive vs. Inverse Mode

What is the difference between the Positive and Inverse Modes of the new SD6432 and SE6432 switches?

SD6432 & SE6432 with Multi-Segment Color MSC™

Introducing the all-new SD6432 and SE6432 switches with Multi-Segment Color MSC™,

NAB 2023 Preview

Preview video of NAB 2023 show exhibit

[E³] highlights new product features at NAB 2023

Find out what new product features [E³] is showcasing at the upcoming NAB show in Las Vegas.

Get a FREE exhibit pass to [E³]'s booth C6938 at NAB 2023

Series Production Start for SC-SD-SE-SR Switches

Initial production runs for all-new switches begin as planned.

The ibc show is back LIVE at the RAI in Amtserdam

Although we are unable to participate this year, [E³] wants you to be able to explore our RGB-backlit LCD switches, control panel solutions and product introductions.

[E³] offers FREE exhibit pass to NAB

Join us at NAB 2022 with a FREE exhibit pass.

[E³] to launch 3 NEW switch versions at NAB 2022

The return to the NAB trade show gives [E³] the opportunity to introduce 3 NEW switch versions with significant product improvements and additional features.

Cleaning and Disinfecting Sxnnnn Switches

[E³] on Ahorn TV

Watch the recent segment on [E³] products at NAB on Ahorn TV, a German language program in Canada.

NAB 2019

Come visit our booth in Hall C 8033 at NAB 2019 in Las Vegas.

[E³] launches revamped website

First we expanded our social media presence, now [E³] has updated and expanded its website as well.

C3 Panels for Military Applications

Command Control and Communications panels for the world's most demanding military customers.

Ready ... Set ...SHOW!

[E³] participates at NAB 2018 with new trade show setup

Oslo Opera House customizes stage controls with custom CP panels

Remote keypad is the solution for stage control upgrade.

Social Media Presence

[E³] expands its social presence in order to provide up-to-date information on the LCD key technology.

YouTube Channel for LCD Keys

[E³] launches YouTube channel to promote LCD keys and provide tutorials on the LCD key technology.

SA switches pass durability testing

Devlin Elctronics subjects SA switches to more than 5 million key presses in durability stress test.

History of the LCD Key Technology

While [E³] was founded in 2001, our history and the history of the LCD technology goes back to 1984.